News

What is laser cutting? High-tech CNC laser cutting application

Laser cutting is a field that has developed greatly in recent years. In particular, CNC laser cutting technology is widely used in mechanical engineering, machinery manufacturing, metal processing: iron, steel, stainless steel… CNC laser technology is increasingly upgraded, and the technological equipment is extremely advanced.

This article will help you better understand cnc laser cutting technology to apply to your work.

What is laser cutting?

Laser cutting is the process of using a laser beam, converging at a point to melt the material, creating other pre-established shapes of materials. The laser cutting process is applied to glass, wood and metal materials such as iron, steel, stainless steel, copper, aluminum, etc.

With the nature of a narrow beam, laser cutting will help achieve extremely high precision. This is the most outstanding point of laser compared to other types of rays such as plasma or oxygen/gas.

See more:

- What are lasers?

To use a laser machine to cut metal, high-power laser sources are required. The laser beam melts, combined with the blowing gas to make the cut circuit brighter and smoother.

Types of lasers used for cnc cutting

Currently, there are 2 popular laser cutting technologies on the market: gas laser (Co2 laser) and fiber laser. Each type has different advantages, but the most popular type today is fiber laser.

Co2 laser cutting: This type of laser is created in a Co2 gas environment. The condition for a gas laser is that the laser light has high adhesion and beam. It is mainly used to cut non-metals, especially plastics, wood, mica, glass, etc.

Fiber laser cutting: Fiber lasers produce very small beams and are 100 times more intense than Co2, so they are often used to cut and engrave metals. Metal is a material with high hardness, so it needs to be processed by a method that ensures the best quality and aesthetics. CNC fiber laser is the most effective metal processing method.

A few years ago, Co2 Laser technology (Co2 laser cutting machine) was the most widely used, however, thanks to technological developments, including modern CNC technology, fiber laser cutting machines are becoming more and more popular thanks to their outstanding advantages. So what is the operating principle of the fiber laser cutting machine that is sought after by the entire steel industry?

Working principle of fiber laser cutting machine.

Fiber laser cutting machine is composed of CNC system combined with laser beam generating system. Laser beam generating system includes laser source and laser cutting head that will emit laser beam. Laser beam is converged and melts metal.

The cnc control system has the function of automatically controlling the movement of the axes according to pre-written equations. The laser beam moves at high speed, creating cutting lines with high precision.

In addition, a CNC laser machine also has a gas system that helps blow away molten slag layers, making the cut circuit shiny and slag-free.

What materials can be cut with fiber laser?

Laser machines can cut most metals such as: iron, steel, stainless steel, copper, aluminum… depending on usage needs.

inox

Laser cutting stainless steel often requires high precision and fast cutting speed, so laser machines for cutting stainless steel are often equipped with the highest quality components. In particular, the machine table when cutting stainless steel often has to endure large acceleration, so the weight of the machine table must be guaranteed.

Stainless steel is a reflective material, so when cutting stainless steel, there is often a decrease in power after a period of use. Therefore, EMC recommends that you choose high-quality power sources to cut stainless steel. High-quality laser sources such as IPG often minimize the decrease in power.

Iron, steel

Cutting iron and steel with CNC laser requires high precision and extremely meticulous details. The accuracy when cutting iron and steel is rated up to 99%. Compared to some plasma cutting methods, cutting iron and steel with laser gives higher speed, more precise cutting lines and almost no slag.

With carbon steel, laser cutting machines can easily handle the most detailed work. With steels with high alloy content, the laser machine operator’s technique is also higher.

Advantages of laser cutting

- High precision, can cut even small details.

- High production speed.

- Reduce production costs.

- Wide material compatibility.

- No risk of contamination.

- Narrower groove width.

- Cut a variety of materials.

- Ensure uniformity between products, no technical errors.

- Can cut many products with high thickness easily.

Disadvantages of cnc laser cutting

- Users need high technology and large investment.

- High investment cost.

Metal cnc laser cutting application.

Fiber laser cutting machine can cut many types of materials with different thicknesses. Therefore, laser cutting machine can be applied to many jobs such as cutting codes, CNC patterns, machine parts…

Cut the ciphertext

Cutting the code with a laser cutter, fast and precise cutting speed, smooth cutting circuit, less burr. For thick code types, it is necessary to choose the appropriate laser source capacity. For example, a 1kw laser cutter can cut up to 12mm of black steel, but with an IPG laser source, it can cut black steel up to 70mm.

CNC pattern cutting

CNC patterns in interior and exterior decoration are becoming popular for villas or townhouses. CNC patterns processed by laser cutting machines have many advantages such as: Diverse designs, sizes, styles, … Helping customers choose the right model for their home.

CNC patterns are usually cnc gates, cnc fences, cnc railings, cnc partitions… These are the most popular cnc pattern products, often chosen by customers for laser cutting. If you have a laser cutting machine, pay attention to the pattern file samples to increase your competitive advantage.

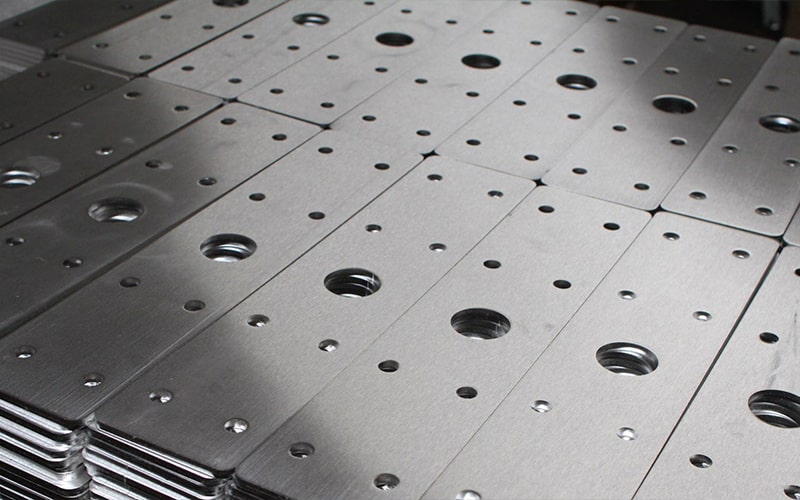

Cut machine parts

High cutting speed and accuracy up to 99%, CNC laser cutting technology is also applied to cutting machine parts. Cutting machine parts with sizes from large to small a few centimeters with absolute precision.

Mechanical manufacturing industry with products such as elevators, industrial kitchens, fans, etc. Including metal parts from large to small. Finished products can be assembled immediately without going through milling or turning.