Metal Stamping – Precision Solution In Mechanical Production

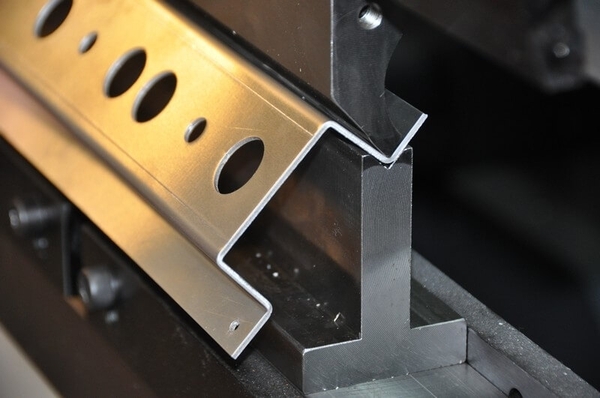

Metal bending is an important step in the sheet metal processing chain, especially in manufacturing industries that require high precision and aesthetics. The combination of modern CNC bending technology and a team of experienced technicians allows the creation of standard, sharp and durable bent products over time.

Optimizing Metal Forming Processes

CNC (Computer Numerical Control) bending technology helps bend metal with high precision and almost absolute repeatability. Thanks to intelligent programming software, the bending process is performed automatically, minimizing operating errors and increasing production speed. In particular, metal bending processing services help businesses save on mold costs, while shortening product completion time.

High Precision – Meets All Technical Designs

Metal bending is not just about bending steel or stainless steel plates, but also about turning design ideas into reality. With modern 3-axis – 6-axis CNC bending machines, we can shape parts according to technical drawings with extremely low tolerances, even for complex shapes or with tight bending radius requirements.

Flexible With Many Materials And Sizes

We accept bending processing for many types of materials such as: steel plate, stainless steel, aluminum, galvanized iron, … with thickness from 0.5mm to 10mm. Whether it is a small-sized product, technical components or large-sized details in the construction structure, we ensure accuracy and consistent quality on each shipment.

Fast Response – Suitable for Both Large and Single Quantity Production

Thanks to the synchronized CNC machine system, we can process orders from small quantities to mass production while ensuring progress and quality. This is the ideal solution for furniture workshops, civil mechanics, industrial electricity or OEM processing projects.

Metal Processing Combining Bending – Cutting – Welding – Assembly According to Drawings

Not only bending, we also provide a full package of accompanying services such as CNC Laser cutting, MIG/TIG welding, grinding, surface treatment and assembly according to technical drawings. This helps customers save time managing multiple processing points, while ensuring consistency in the quality of all output products.

Commitment From Technical and Service Team

- Modern CNC bending equipment: imported from Japan and Europe

- Skilled technical team: understanding the materials and processes of bending

- Strict quality control process: from drawing, sample to final product

- Flexible delivery times: meet even urgent, short-term projects

- Free technical advice: support from design to production optimization

We Are Your Trusted Partner For Every Metal Fabrication Project

With practical experience in the mechanical and sheet metal processing industry, we are confident to accompany businesses in the fields of interior design, construction, electrical engineering, automation, etc. in all large and small projects. Our metal stamping service is not simply technical – but the optimal solution to bring your product from drawing to reality, on schedule and beyond expectations.