Metal Stamping – The Ultimate Solution For Precision Industrial Production

In the field of modern mechanical manufacturing, metal stamping is one of the key steps to help shape products quickly, accurately and cost-effectively. With strong equipment capacity and a team of highly specialized technicians, we provide metal stamping services on demand – from simple details to complex components, serving a variety of industries.

Optimize Costs – Increase Productivity

Stamping is the ideal solution when it comes to producing large quantities of highly accurate, repeatable parts. By using a dedicated stamping die, the entire process is mechanized, which reduces labor costs, saves time, and makes quality control easier. Compared to traditional machining methods, metal stamping offers superior efficiency in large-scale production lines.

Diverse Dies – Flexible In Application

We design – manufacture – process according to many stamping methods such as:

- Cold stamping: suitable for stainless steel, steel plate, aluminum, copper with thin thickness

- Hot stamping: applied to parts that need deep shaping or thick materials

- Continuous stamping: helps increase production speed, suitable for large orders

- Single stamping: small part production, prototypes, precision engineering products

Each method is selected and implemented depending on the material properties, shape complexity and required machining output.

Metal Stamping According to Drawings

Our service supports stamping according to technical drawings or actual samples. Our team of engineers is capable of reading and understanding 2D/3D drawings accurately, thereby advising on the selection of stamping methods, materials, and mold design options that best suit the technical requirements and budget of customers.

Common Processing Materials

We have experience stamping a variety of materials:

- Steel CT3, SS400, S45C

- Stainless steel 201/304/316

- Galvanized steel, cold rolled steel

- Aluminum, copper, light alloys

Thickness control capability from 0.3mm to 8mm depending on material and type of stamping machine.

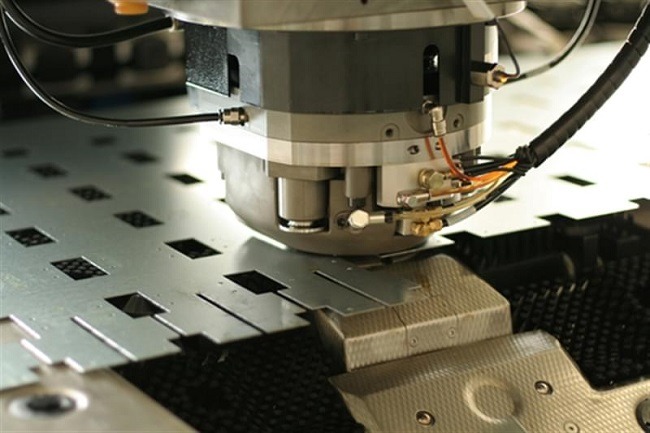

High Power Stamping Equipment

Our stamping system includes:

- Mechanical presses: from 25 tons to 200 tons – suitable for most common applications

- Hydraulic press: from 100 tons to 500 tons – specialized for deep stamping, thick materials

- High speed continuous stamping machine: optimal for products requiring high productivity

All equipment is regularly maintained and integrated with an automatic control system to ensure absolute consistency and precision on each product.

Advantages of Using Our Stamping Services

- High precision, low error below 0.1mm

- Large, stable output, on-time delivery

- Technical consulting – free mold design according to needs

- Strict quality control at every stage

- Full service: design – mold processing – stamping – surface treatment

Wide Application In Many Industries

Metal stamping has a wide range of applications:

- Mechanical components – industrial machinery

- Auto, motorbike, electric vehicle spare parts

- Electrical cabinet frame, cable tray

- Details of interior and metal decoration industry

- Construction materials – light steel structures

We are committed to providing comprehensive machining solutions that meet even the most demanding requirements in the engineering and industrial manufacturing sectors.

Commitment to Quality and Reputation

With the motto “Precision – Durability – Synchronization”, we constantly upgrade our equipment and working processes to meet all expectations of our business customers. From small orders, samples to producing thousands of parts per day – we are committed to maintaining stable output quality and on-time delivery.